How to scale up carbon capture and storage

Industrialising a nascent technology that’s critical for net zero targets

1 minute read

Simon Flowers

Chairman, Chief Analyst and author of The Edge

Simon Flowers

Chairman, Chief Analyst and author of The Edge

Simon is our Chief Analyst; he provides thought leadership on the trends and innovations shaping the energy industry.

Latest articles by Simon

-

The Edge

What next for East Med gas?

-

The Edge

Why upstream companies might break their capital discipline rules

-

The Edge

Walking Japan’s energy tightrope

-

The Edge

No country for oil men (and women)

-

The Edge

Battery energy storage comes of age

-

The Edge

CCUS’s breakthrough year

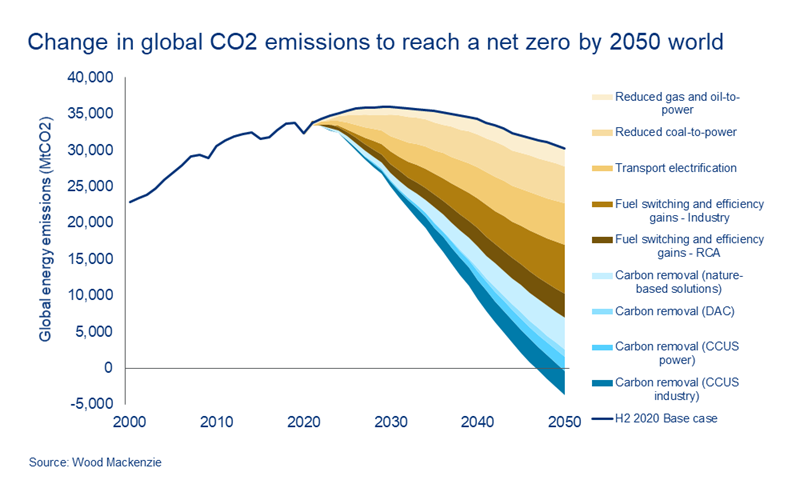

Carbon capture and storage is starting to happen. A plethora of CCS projects has emerged in the last year, large and small in scope, in upstream and LNG, as well as energy-intensive industries beyond the oil and gas value chain including the power, steel, cement and fertiliser sectors. This spate of individual projects is a promising sign for a technology on which much hope rests – CCS could account for one third of the emissions reduction required to meet the global net zero target by 2050.

But CCS is still a cottage industry. Neeraj Nandurdikar, Vice President Consulting, and Amy Bowe, Head of Carbon Research, authored Horizons: Location, Location, Location – the key to carbon disposal. I asked them how CCS gets big and pan-sector.

How important is CCS to decarbonisation?

CCS today is a tiny part of the story, accounting for less than 1% of the 33Gt of annual global carbon emissions. It’s going to be massive in the future – we estimate CCS capacity will increase from 56Mt today to between 4GT and 8GT by 2050 if the world is to meet the promise of the Paris Agreement.

CCS could account for one third of the emissions reduction required to meet the global net zero target by 2050.

Renewables alone can’t resolve the net zero emissions challenge. We have to think in terms of carbon avoidance and carbon removal. That means accelerating the upscaling of carbon capture and storage, starting now. Without CCS technology, the 750 Gt carbon budget for a 2-degree pathway will be exceeded by 8% in our AET-2 scenario.

Why isn’t it happening now?

The world has been experimenting with CCS since the early 1970s. Around 68 projects started and terminated, primarily because the projects are super-expensive. Policy support is a pre-requisite to support the economics, including a minimum carbon price of US$90/tonne for most industrial applications at scale. For difficult-to-decarbonise sectors like steel it’s up to US$120/tonne; and for cement can be up to $200/tonne.

The other big factor holding back CCS is that development today is scattergun. Individual companies, start-ups and think tanks are working on specific industry- or technology-led solutions. The current array of CCS projects suggests that developers favour economies of scope (or specialty), and focus solely on, say, capture or transport.

What’s the solution?

We can’t just wait for innovative technologies and new policy and regulatory design. We have to think of different and radical ways to solve the problem and challenge our traditional business models and ask whether they are up to the task.

‘Coopetition’ is the way forward, joining forces with the competition to identify concentrated clusters of carbon emissions, shared transport infrastructure and basin-wide storage. We call it carbon clusters linked to storage, or CCLSTR.

We have to think in terms of carbon avoidance and carbon removal. That means accelerating the upscaling of carbon capture and storage, starting now.

How can CCLSTR transform CCS?

The key to success will be to move away from a fragmented approach and create a carbon disposal industry. CCLSTR is about scaling up and reducing costs through economies of scale. The maximum synergies for CCS will be where point sources of emissions and the storage site are closest to each other.

Large volumes of CO2 emissions from clusters of industrial processes can be pooled together - refineries, petrochemical plants, gas processing plants, LNG plants, power plants and metal (such as steel and aluminium) refineries and smelters. The CO2 is then transported en masse to viable geological storage sites such as depleted oil and gas reservoirs or saline aquifers. Existing pipeline infrastructure connecting the point source to storage is a bonus, saving up to 75% on transportation costs compared with a new pipeline or using ships.

How do you identify potential CCLSTRs?

You need the right data and tools. Using WoodMac’s Lens Subsurface data and Emissions Benchmarking Tool we identified 1500 depleted oil and gas fields that are technically capable of storage. Our asset-level emissions benchmarking tool also enables us to map industrial point-source emitters. We then screen those storage sites close to industrial clusters in basins with no existing CCS projects. Three of four case studies were determined as viable for CCUS hubs based on technical considerations.

Can CCLSTR bring stakeholders together?

Yes. Basin-wide carbon capture is the quintessential complex venture problem. The data to screen CCLSTR opportunities can give multiple interested parties common ground to advance basin-wide carbon capture. Stakeholders can use the data to have discussions on specific clusters and specific assets, calculating their emissions and mapping them to specific storage sites with the right geological properties.

Much of the requisite technical data exist already. Wood Mackenzie developed CCLSTR using its own comprehensive datasets. This gives stakeholders – companies, regulators and policymakers – a basis for grounded discussions on what needs to happen to make a specific cluster-to-sink a reality.